Odds are, when you were in middle school, you weren’t building a boat from scratch. That is unless you’re Redditor BenderRodriguezz. After saving up a bunch of money, he bought plans to make a motorboat from start to finish. What he and his dad probably didn’t realize was just how much work the whole undertaking would end up being…

Ten years later, he launched the boat for the first time. Here are just some of the steps he took to make his boat, Current.

After saving up his allowance and birthday money, BenderRodriguezz bought plans and got to work cutting out the needed pieces from panels of plywood.

This temporary frame was assembled for a process that BenderRodriguezz says is called stitch-n-glue.

Basically, he stitched together the pieces of plywood with copper wire.

Slowly but surely, the hull began to take shape.

The next step was to fill every seam with glue. BenderRodriguezz cut all the copper wire away and covered the seams with strips of fiberglass cloth and epoxy.

This was the tiny garage BenderRodriguezz and his dad had been working out of.

By the time they started putting fiberglass on the exterior, four years had already passed!

He sanded things down…

And added the first coat of paint!

BenderRodriguezz graduated from high school — at that point, they’d begun work on the deck and the electrical.

While he was in college, work was slow on the boat. Here BenderRodriguezz and his dad are clamping and gluing African mahogany strips around the hull.

The sanding process took ages. “I still have nightmares about the sanding,” the builder commented.

When the varnish went on, his boat really started to shine.

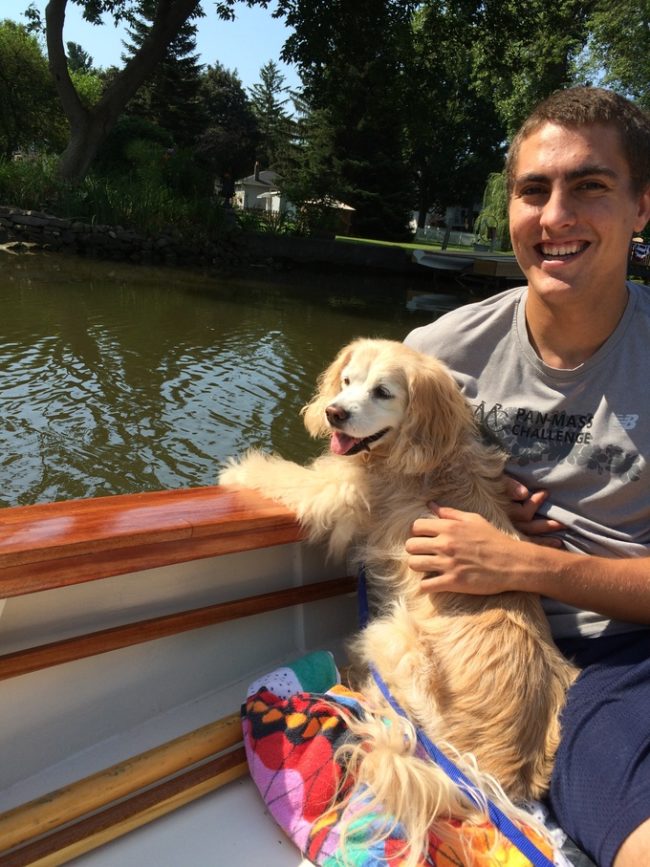

And here she is! Ten years of work and well worth the wait.

Of course, there were tons more steps along the way, but you get the idea — this boat was an undertaking! If you’d like to see the whole process, check it out here.

Comments